Gainsharing

What is gainsharing?

Gainsharing aims to increase company profitability by seeking higher levels of participation and employee performance. Employees receive a financial share of the profit of the company gained by a performance improvement they helped design.

Gainsharing aims to eliminate waste in processes and motivate employees to work hard. It’s a group-based initiative in which employees work together to improve performance, which results in financial gains for the organization.

What does improved performance mean?

Depending on the industry, improved performance can mean different things. However, it should be measurable and observable. Some examples of improved performance could be:

- An increased level of customer satisfaction

- Reduction in hours of a particular process

- An increase in the number of sales

Specific targets need to be agreed on beforehand. In most cases, a 1% improvement is probably not enough to be considered a significantly improved performance.

How does gainsharing work?

A typical gainsharing program uses a formula to calculate the shares to be split among employees. Improved performance is measured against baseline performance. Any gains made can be assessed monthly, quarterly, or annually.

Typically, gainsharing is measured against operational metrics (efficiency, waste reduction, cost reduction, etc.), as employees can directly contribute to controlling these. You will often find these types of plans in the healthcare, manufacturing, or service industries.

- Gainsharing is self-funded – i.e., the gains made are contributed by the employees who have contributed to the improvement.

- Employees are typically involved in creating the parameters for the gainsharing program.

- Gainsharing works best in a collaborative and supportive culture.

Gainsharing examples

1. A laptop manufacturing company

Imagine a company that produces laptops. In the previous month, they produced 10,000 laptops in 5,000 working hours. After the group came together and worked on various ways to make their process more efficient, they produced 10,000 laptops in 4,000 hours during the following month, which resulted in savings of $150,000.

The gains are then split equally among the group in the company. This is an example of gainsharing in which a group of workers improved efficiency.

2. A car manufacturing company

Another example of successful gainsharing is a group effectively thinking of ways to reduce costs. A car manufacturing company noticed approximately $5,000 in waste material for every vehicle produced.

Using a gainsharing program, the group strategized, and they managed to reduce the waste to $3,000 per car produced. In a month, when the manufacturer produces 50 cars, that’s a cost reduction of $100,000. This amount was shared between those involved in the project.

3. Xerox gainsharing plan

Xerox, a print and digital document products and services company, implemented a gainsharing plan aimed at motivating employees and enhancing work efficiency.

The gainsharing program led to significant operational improvements, including enhanced employee motivation and cost-efficiency in manufacturing processes. Employees, recognizing their direct impact on product quality and cost savings, were more engaged and proactive. This engagement was reflected in the company’s productivity, with the gainsharing scheme contributing to measurable increases in efficiency and a reduction in waste.

Financially, the plan resulted in gainshare bonus payments to employees, averaging around 2% of their salary, incentivizing higher performance and aligning employee goals with company success.

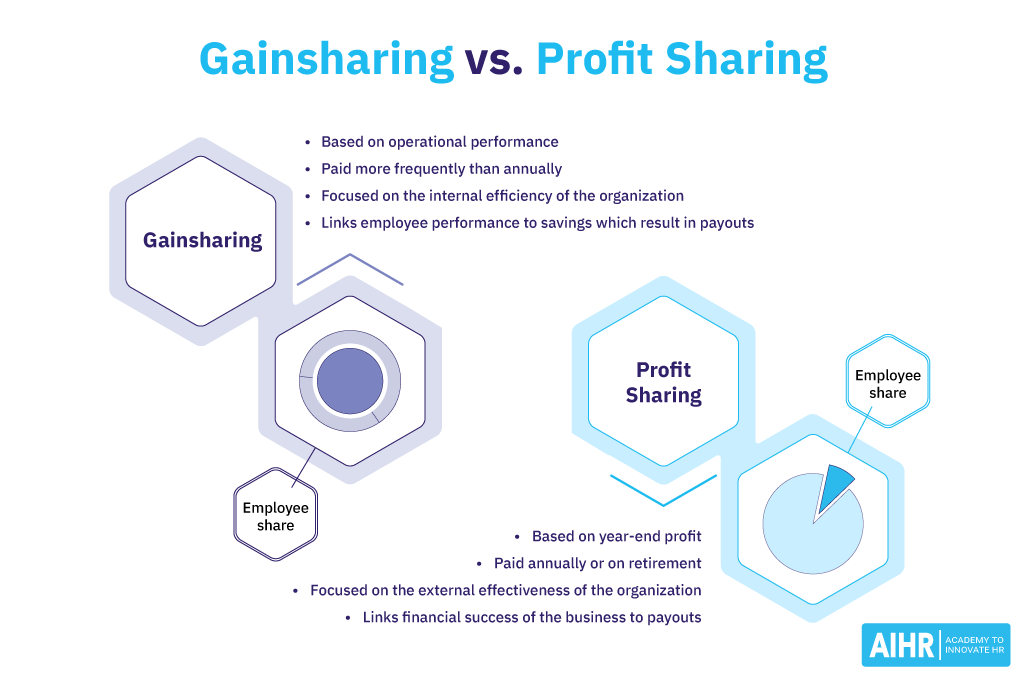

Gainsharing vs profit sharing

Gainsharing systems typically have a more frequent potential payout. Profit-sharing systems typically pay out on an annual basis. Of course, the closer rewards are tied to performance, the greater the motivational impact of the potential reward.

In profit-sharing plans, rewards for employees are always directly tied to the company’s overall profitability. The higher the profits, the bigger the profit sharing. On the other hand, gainsharing requires specific improvements not always tied to profitability. This could, for example, be an increase in sales or a reduction in costs.

Here’s a summary of the differences between gainsharing and profit sharing:

Objective

Encourages specific performance improvements and efficiencies within teams or departments

Rewards employees based on the overall financial success of the company

Basis for rewards

Based on specific improvements (e.g., sales increase, cost reduction) not always tied to profitability

Directly tied to the company’s overall profitability; the higher the profits, the bigger the sharing

Frequency of payout

More frequent potential payout, often quarterly or monthly

Typically annual payouts

Motivational impact

High, due to the close tie between rewards and immediate performance

Can be high, but the annual payout may dilute the immediate motivational impact

Types of gainsharing plans

The Scanlon plan

The Scanlon plan is predominantly concerned with output. It takes any savings and splits them between the employees and the company. The saving is based on the standard labor cost per unit minus output subtracted from the actual labor cost per unit of production.

For example, if an employee works 10 hours per day and has to fix 15 air conditioners per day at an hourly rate of $15, their earnings would be $150 per day. As a result of implementing the Scanlon plan, the employee now fixes 20 air conditioners per day. The gains would be the difference between the rate of producing 15 and 20 air conditioners per day.

The Rucker plan

The primary focus of the Rucker plan is to look at the quality produced and not the quantity. This is suitable in industries where productivity does not have varying levels, but rather the quality of the product produced is held in higher regard.

The typical variable used in the Rucker plan is waste-to-production ratios. Another potential metric could be ‘number of defective parts per production.’

Improshare plan

An Improshare plan is similar to a Scanlon plan, but instead of the cost of labor, it uses the number of production hours. When productivity is greater than the initial measured baseline, the difference in savings is shared among employees.

Improshare is calculated based on the team’s overall productivity, so interaction and support are among the primary outcomes of this type of gainsharing.

Worker ownership

With worker ownership, an employee can gain extra income through their performance and own actual shares in the company.

Gainsharing pros and cons

Pros:

- Gainsharing helps a company improve its performance levels, as employees are motivated to perform well.

- A company saves money as the payout for performance improvement is self-funded.

- Individual efforts are calibrated to the team and organizational goals.

- Costs are reduced.

- Efficiency is enhanced.

- A culture of support is created within the workplace.

Cons:

- Sometimes payouts have to be made even though the company is performing poorly.

- It could cause friction and entitlement in the workplace.

- It can increase stress as everyone is pushing towards a financial goal.

- Individual merit can be overlooked as the emphasis is placed on team goals.

- There may be decreases in other areas that aren’t being incentivized, such as safety ratings.

FAQ

A gainshare bonus is a financial incentive awarded to employees based on achieving specific performance improvements, such as cost savings or productivity increases, not directly tied to the company’s profitability. To closely align rewards with these performance improvements, gainshare bonuses are typically paid out on a quarterly or monthly basis.

Organizations use gainsharing plans to motivate employees to work more efficiently and improve specific performance metrics, such as productivity or cost savings. These plans aim to foster a team-oriented culture by aligning employee efforts with organizational goals. This encourages collaboration and shared responsibility for success.

An example of gainsharing in healthcare could involve a hospital implementing a program where surgeons and surgical staff receive bonuses for reducing the cost of surgical supplies without compromising patient care. If the team switches to equally effective, less expensive supplies and practices, leading to significant savings, a portion of those savings is distributed as bonuses to the team members involved.